Our Process

Pure Cow Milk

UB delivers you hygienic, chemical free milk, freshly collected from local farmers.

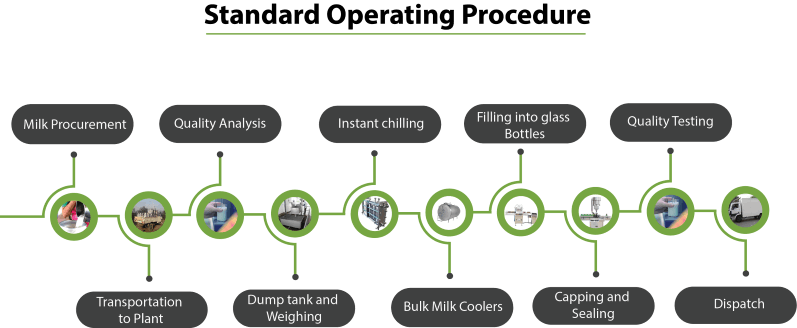

Cows are hand-milked twice a day. The milk is collected from the farmers within the radius of 10kms from the plant. Before the milk enters the Milk Processing Plant, a sample is taken for quality analysis. These samples are tested for milk fat, SNF, density and microbial quality. After quality analysis tests, the milk is pumped into the bulk milk chiller, and is refrigerated to favorable temperature to prevent enzymatic and microbial changes. Then the milk flows into a filling machine and is filled in clean glass bottles. If the sample fails to meet the expected standards, it is discarded.

Pure Cow Ghee

UB's ghee / clarified butter is traditionally made from pure cow milk.

Fresh milk is taken and cream/fat portion is separated using a cream separator. The cream is then added with starter/natural curd and is left to ferment, allowing the growth of lacto bacillus. The ghee now is churned to separate butter and is drained using a muslin cloth to remove excess water. It is then boiled in a double walled vessel at a medium temperature. A pinch of salt is added to initiate coagulation of proteins and to separate the fat from the proteins. The extracted clear liquid is then filtered and filled into clean glass bottles.